Working with KeySplint Soft 3D Printed Occlusal Guards

I 3D print a lot… and have been do so for years in my dental office. Why? First… it’s just fun, but, in reality, we are making things that solves and/or serves a need. In Dentistry, clinical necessity is the mother of development [i.e. invention]! We have the need to produce things in our dental office like models, surgical guides, occlusal guards, and more! In fact, I wrote an article about why I think 3D printing is perfect for dental offices and how to get started.

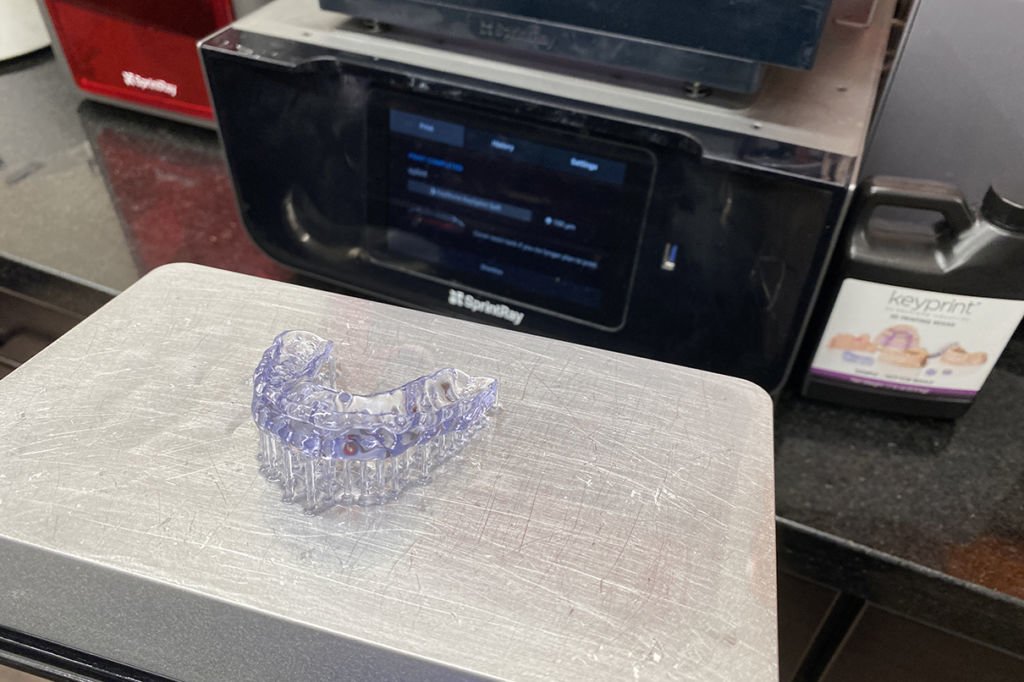

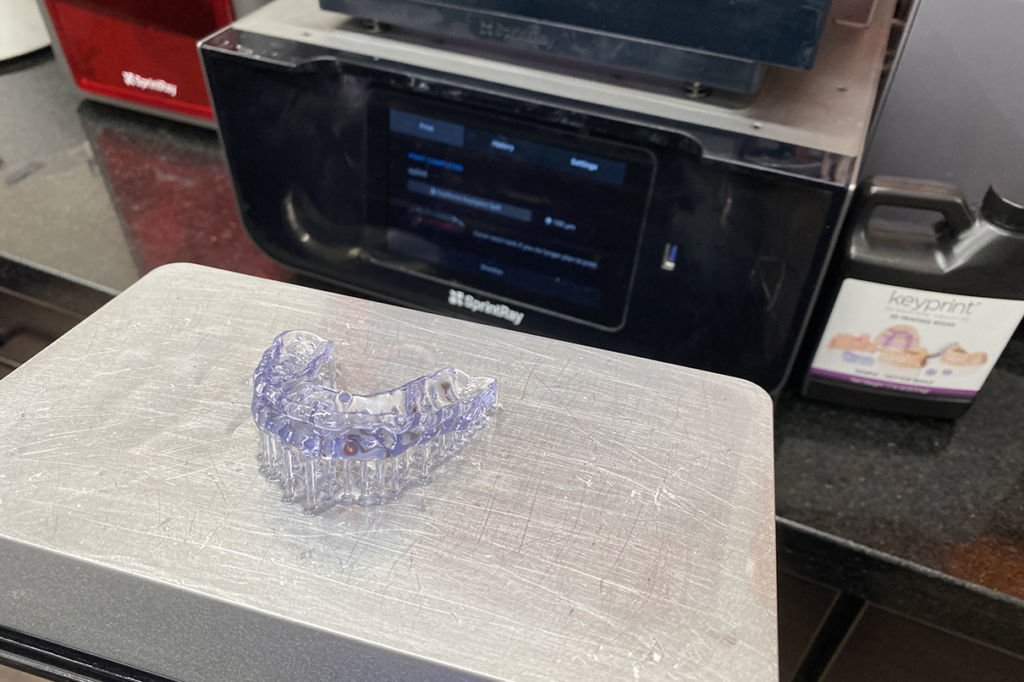

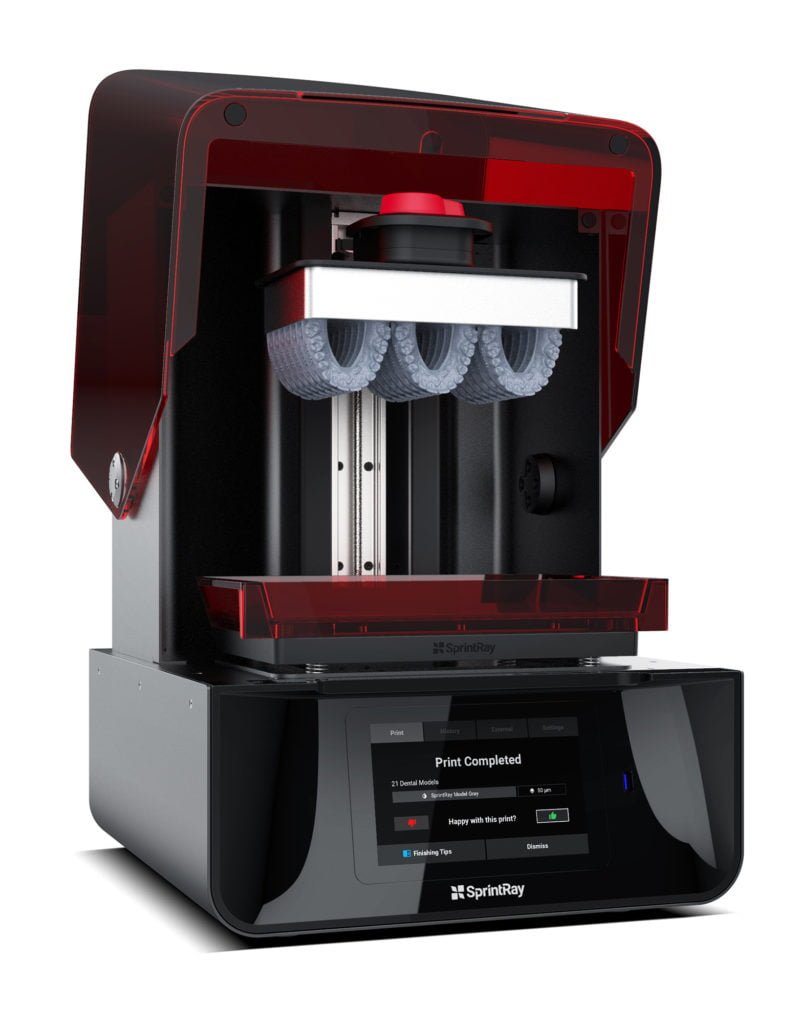

SprintRay Pro 3D Printer

I have been printing occlusal guards for a long time because I had that need. I just felt like I was going crazy having to wait 2 weeks for a custom laboratory processed occlusal guard, paying a sizable laboratory bill, and ultimately having to spend so much time adjusting the guard because it was fabricated from high shrinkage heat processed acrylic resin. Not to mention my patients tolerate but hate physical impression material like alginate or polyvinylsiloxane.

In Dentistry, clinical necessity is the mother of 3D printing development [i.e. invention]! “

Michael D Scherer, DMD, MS

Enter digital dentistry and 3D printing… “the clinical need for something” as I alluded to earlier. I had a need for using intraoral optical scans and generating physical models. I had a need to use those models to make surgical guides and occlusal guards.

So I experimented using earlier versions of biocompatible resins like Nextdent SG and also analog-digital pathways of indirectly fabricating guards using 3D printed models on a physical articulator. A pain, but it worked.

Then Nextdent developed their Ortho Clear material and Formlabs got it to work well on their Form2 printer under the label Dental LT Clear (note: I helped Formlabs launch the LT Clear Resin…). I enjoyed working with various brands of 3D printed occlusal guards and each had their own pros and cons. The biggest negative was that 3D printed guards were a bit brittle and there seems to be a delicate dance between fitting too loose and fitting too tight. I printed a ton of guards and still have many of those early guards in service. Have I had to replace some? Sure, but thankfully most are doing just fine.

Fast forward to today, and while there are many occlusal guard resins now on the market, one in particular gains some attention. Keystone Industries received FDA clearance / 510k registration for an innovative new 3D printing resin – KeySplint Soft late 2019. The resin is biocompatible, class IIa certified, which means they can be safely used in the mouth for an extended period of time.

Why is KeySplint Soft compelling for the 3D printing dentist? First, it’s simple to print and fully open on any printer using their settings, fairly simple to post-process, and precise to adjust the fit. Additionally, one of the most compelling aspects of the KeySplint Soft resin is that you can warm it in a bowl of warm water or run it under a warm stream of water and get the resin to “loosen up a bit” and allow it to be softened a bit prior to placing onto teeth. This helps solve the problem of needing to spend time trial and error adjusting settings to get the fit just right with some 3D printing resins. With a resin that turns soft after running under warm water, I can design the guards in software to have a “tight fit” yet they feel comfortable when inserting after warming.

(right, after running under warm water)

I currently have 9 3D printers in my office. Why 9? Since 3D printers are relatively affordable, I tend to purchase machines inspired for specific tasks as they become developed. I didn’t purchase a SprintRay Pro 3D printer specifically for using this material, but in my opinion, it’s a good reason to buy one! Frankly, I already have one that my in-house orthodontist loves using for aligner models. Jumping into occlusal guards? They have printer settings for KeySplint Soft resin also, it works perfect.

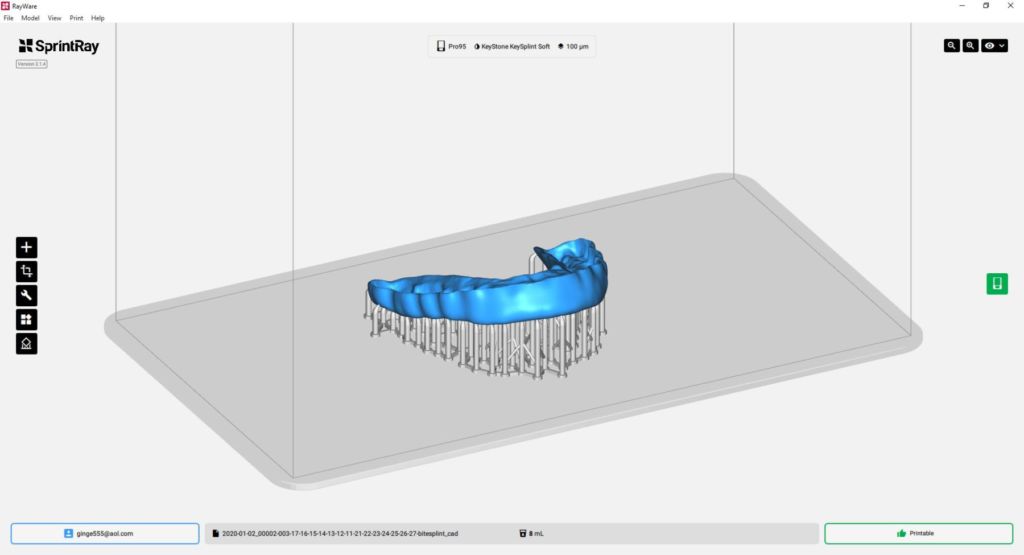

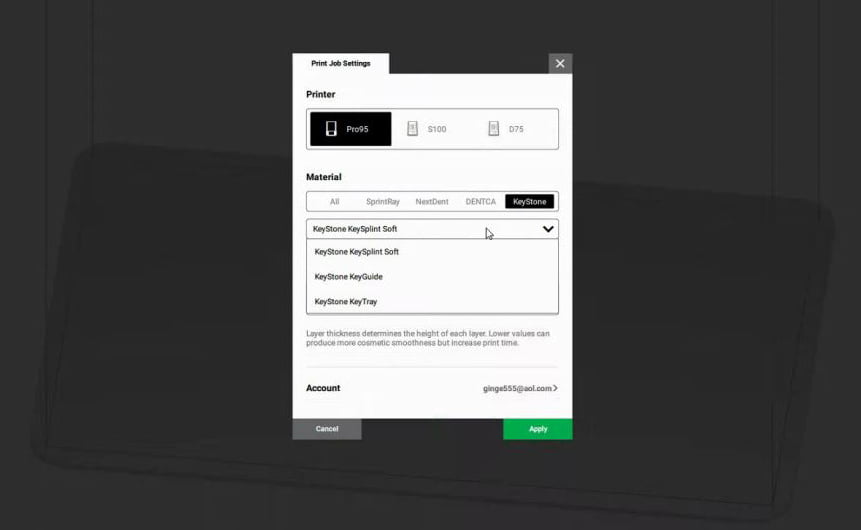

In fact, I can easily import my designed occlusal guard STL file into Rayware Software, select “KeySplint Soft,” and print away. Plug and play 3D printing is what keeps dentists excited about incorporating digital dentistry and using 3D printers.

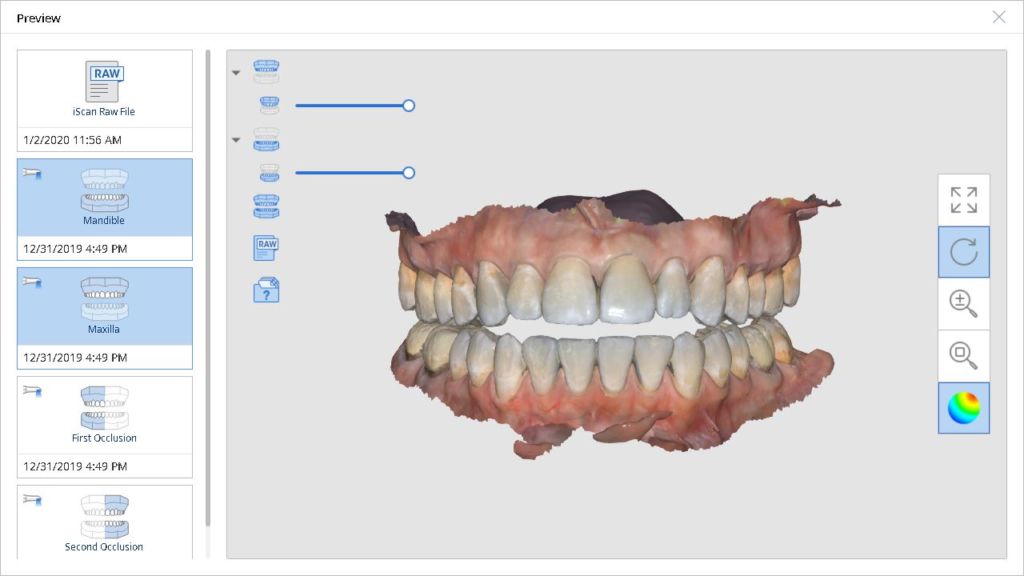

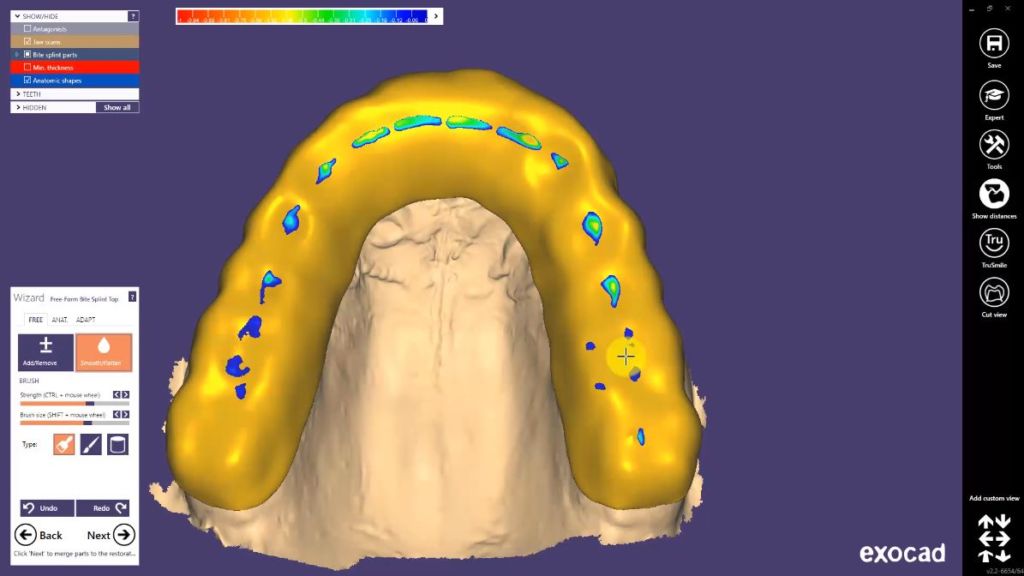

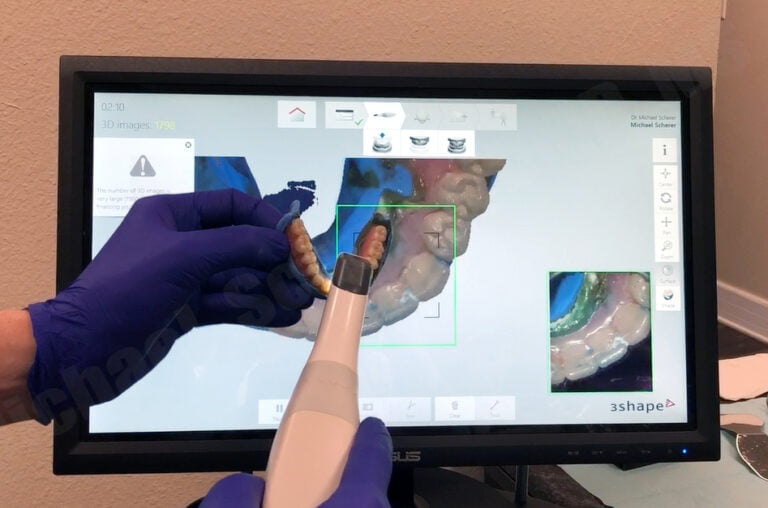

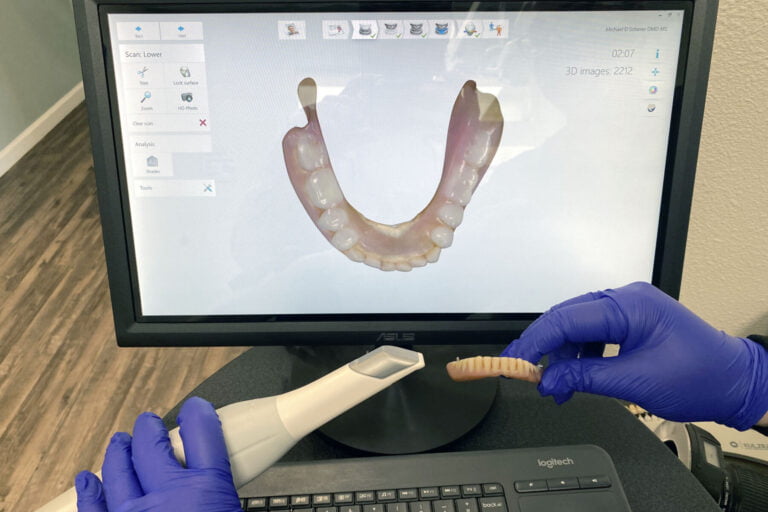

When I got my hands on the resin, I found my perfect test patient, our orthodontist, Dr. Melissa Shotell! She has been wearing an occlusal guard for over 20 years (I’ve made two of them before for her!) and frankly I probably have caused as much grinding as I have helped with the guards I have made for her. A good place to start is with a high quality intraoral scan. I scanned her with my Medit i500 intraoral scanner; scanning the maxillary arch, followed by the mandibular arch, and scanning her bite at a slightly open vertical using a special device called a “leaf gauge.” If you don’t have a leaf gauge, you could could use a lucia jig, a piece of wax, or even a cotton roll to help separate the teeth. After the scans, I exported from the intraoral scanner directly into exocad software. I designed her guard in approximately 10-15 minutes, then exported it directly to Rayware software.

KeySplint Soft is available in two resin cartridge sizes: .5kg (500mL assuming 1kg =1L MSRP $244 USD) and 1kg (1L assuming 1kg =1L MSRP $425 USD). The resin is supplied through major distributors like Pearson Dental and several others. While the smaller bottle appears to be designed for smaller printers, the .5kg bottle just fills the SprintRay Pro resin tray up to just past the minimum line. In the future, I will order it in 1kg at a time to ensure that I have plenty to print with at all times on my Pro. It also comes in two different colors, clear and slight violet tint. Currently at the time of publishing of this article, the clear is only available for Carbon 3D printers but violet is available for any 3D printer. Hopefully in the future that will change, but my patients just really don’t care if their occlusal guards have a slight tint to them!

After filling the resin tray, I clicked the print icon on the Rayware software and, less than an hour later, the guard came out of the printer. I took the guard through a post-processing technique using alcohol washes and placed the guard into Sprintray Pro Cure UV curing box. After UV curing, I finished and polished the guard to ensure it would fit onto my patient’s teeth. (Full technique videos are available on this new online course)

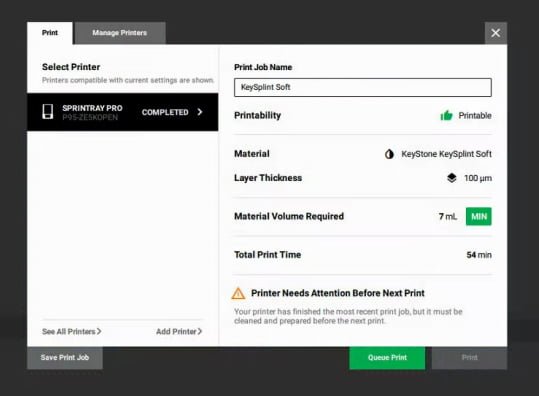

Rayware software

So taking a look at the timing and costs, are 3D printed occlusal guards a smart decision to incorporate into dental practice? Assuming it takes 1 hour to print (mine printed in 54 minutes), I could in theory tell the patient to hang out in the chair for a while as I print their guard! Super cool value-add for some patients who are highly motivated for same-day dentistry.

Looking at the costs, which is very important to many dentists and technicians!

Rayware software indicates that I will use a total of 7mL of the resin to print on my SprintRay Pro printer. So if a 1kg/1L bottle is $425 (MSRP) and there’s 1000mL in the bottle, each mL costs approximately $0.43 (rounded up from $0.425). So if Rayware says my guard uses 7mL, then my resin cost is just shy of $3.00 ($0.425 x 7 = 2.975) total resin costs. Assuming a 7% tax rate and $15 to ship the bottle to you (variable costs depending upon your practice location), each bottle shipped is around $470. Wow, sounds expensive right? Well, we as dentists get so penny wise and pound foolish sometimes about materials… those variable costs only adds about $0.30 to each guard. So that makes the total cost of our 3D printed occlusal guard only $3.30 in material costs. Yes you need to purchase a 3D printer (and intraoral scanner, and wash station etc) so I can’t argue that. Also, there’s time to design, to clean-up, to process the guard, which comes easy to me since I’ve been working with 3D printing for a while. All of those factors should be taken into consideration prior to getting involved in 3D printed occlusal guards.

In reality, occlusal guards at only around $3-4 each are very affordable to 3D print. Comparing to milled guards, where average PMMA disc costs drive up the cost of the guard to close to $10-30 each guard, the clinician has an excellent alternative at their disposal. Impressive!

OK let’s get back to our patient!! After having the guard soaking in a warm bowl of water for about a minute, I removed and placed the warmed guard onto her maxillary teeth and boom… it dropped right in. In addition, the occlusion was very close from the beginning. I did have to adjust the occlusal contacts and excursions, for sure, but in reality my clinical delivery appointment was barely 10 minutes including polishing and teaching the patient how to insert and remove the guard.

Some are calling this resin as “a game-changer!” While that may or may not be true as there are some impressive features, what I do know is that I really do like this material. Like a lot. I can’t wait to print more for my patients!

In reality, how I feel about the material is less important compared to how the patient feels. Let’s see what the patient thinks after having worn her 3D printed occlusal guard overnight!!

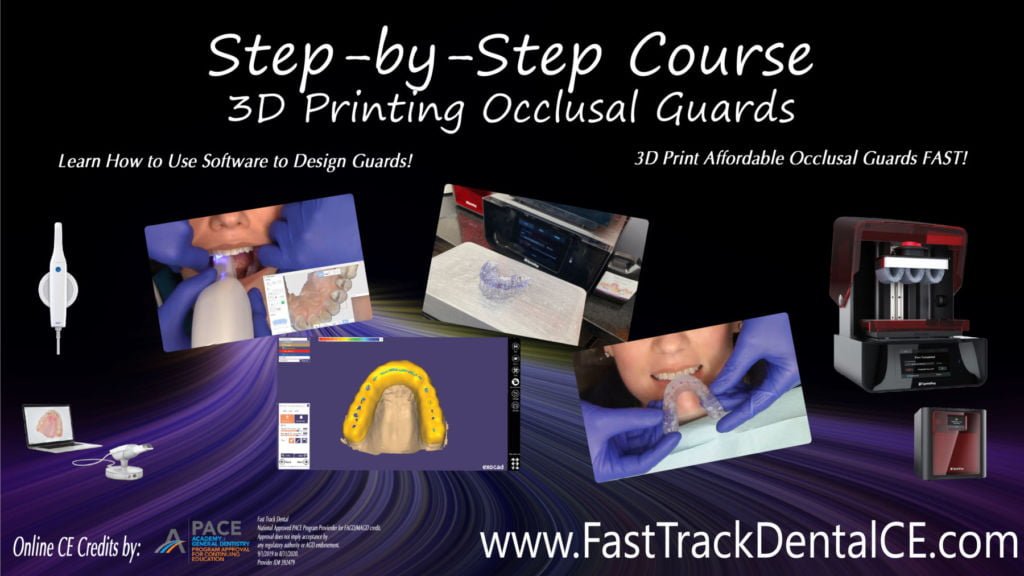

Want to learn step-by-step procedures of making occlusal guards like with KeySplint Soft? We have launched a new online course that is all about 3D printed occlusal guards. Includes videos and clinical procedures on how to work with intraoral scanners, design software, printing occlusal guards, finishing guards, and clinical delivery procedures!

Dr. Michael Scherer, DMD, MS

Dr. Michael Scherer is an Assistant Clinical Professor at Loma Linda University, a Clinical Instructor at University of Nevada – Las Vegas. He is a fellow of the American College of Prosthodontists, has published articles, books, and in-person and online courses related to implant dentistry, clinical prosthodontics, and digital technology with a special emphasis on full-arch reconstruction.