Double Arch Allon4 Immediate Prosthesis with exocad Plovdiv – Milled Prosthesis!

We have been working with digital dentures and AllonX bridges for years now but the biggest challenge has always been the software side of design. For a long time, 3Shape has been the leader in software design of digital dentures… for good reasons. It’s simple, efficient, and just works. At the IDS show in 2019, exocad was talking about launching their own digital denture workflows, I was intrigued. When I finally got a final version of it in my office, I started out smart, making a simple immediate denture, but I quickly needed to grow that into working with digital AllonX conversion prostheses.

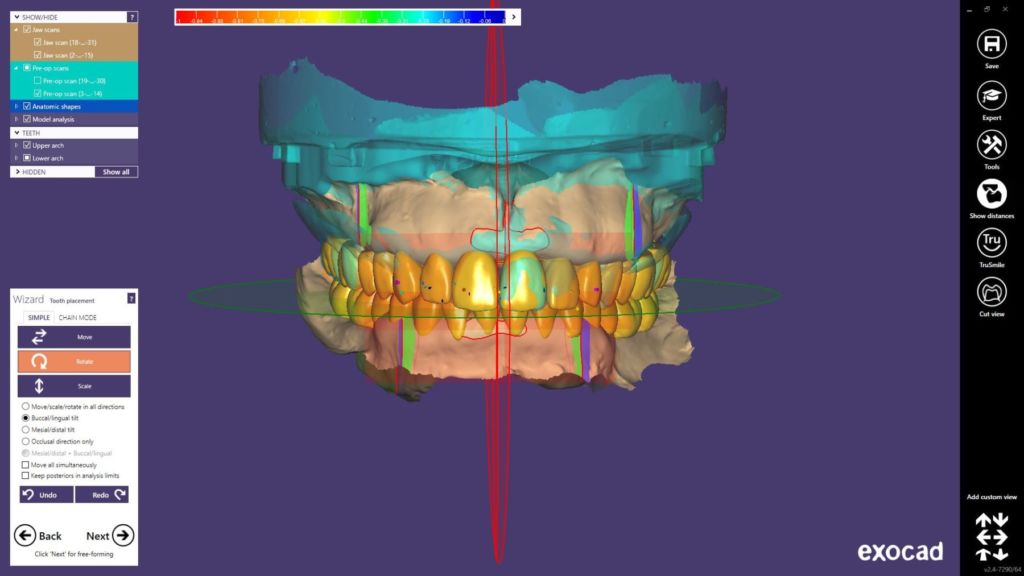

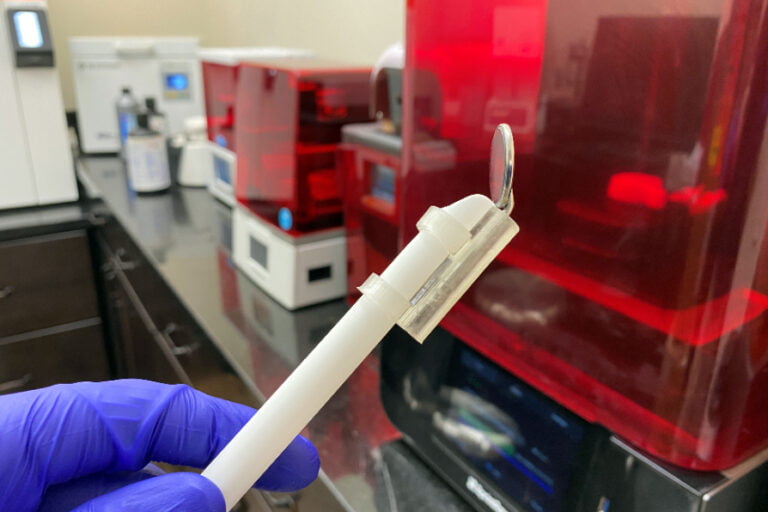

Using our 3Shape Trios scanner, we scanned his maxillary and mandibular teeth intraorally. Using his existing vertical dimension and anatomical landmarks, it made scanning simple! We then brought the scans directly into exocad software where existing teeth were virtually extracted using the built-in exocad tools (no meshmixer needed!)

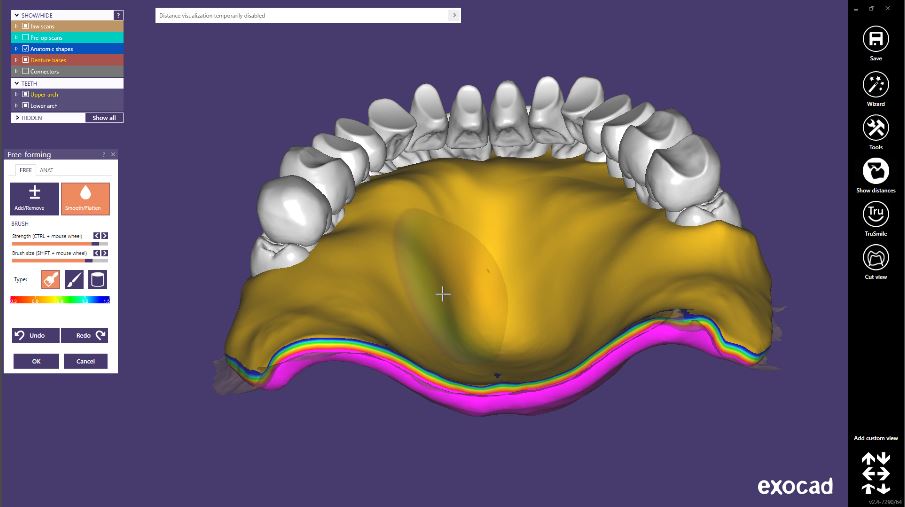

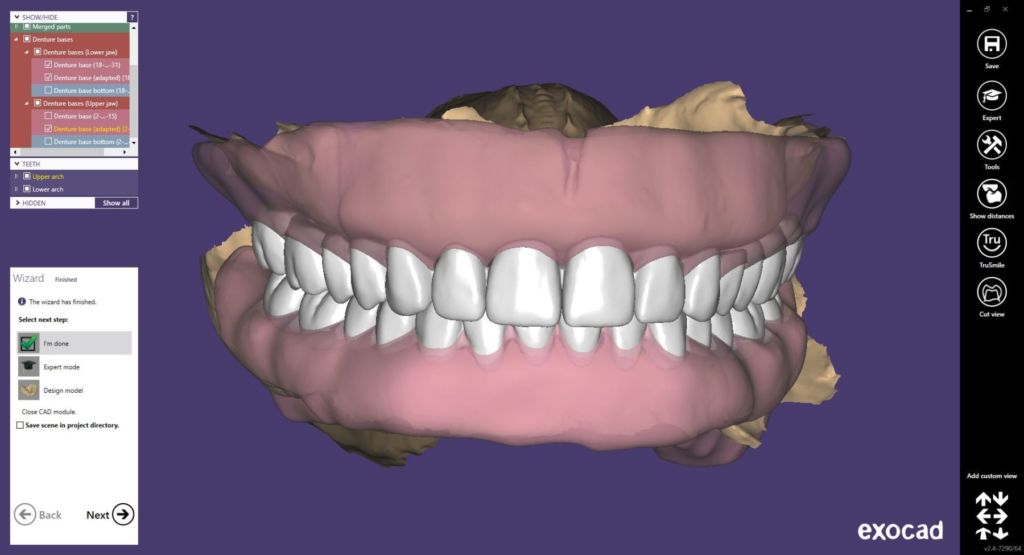

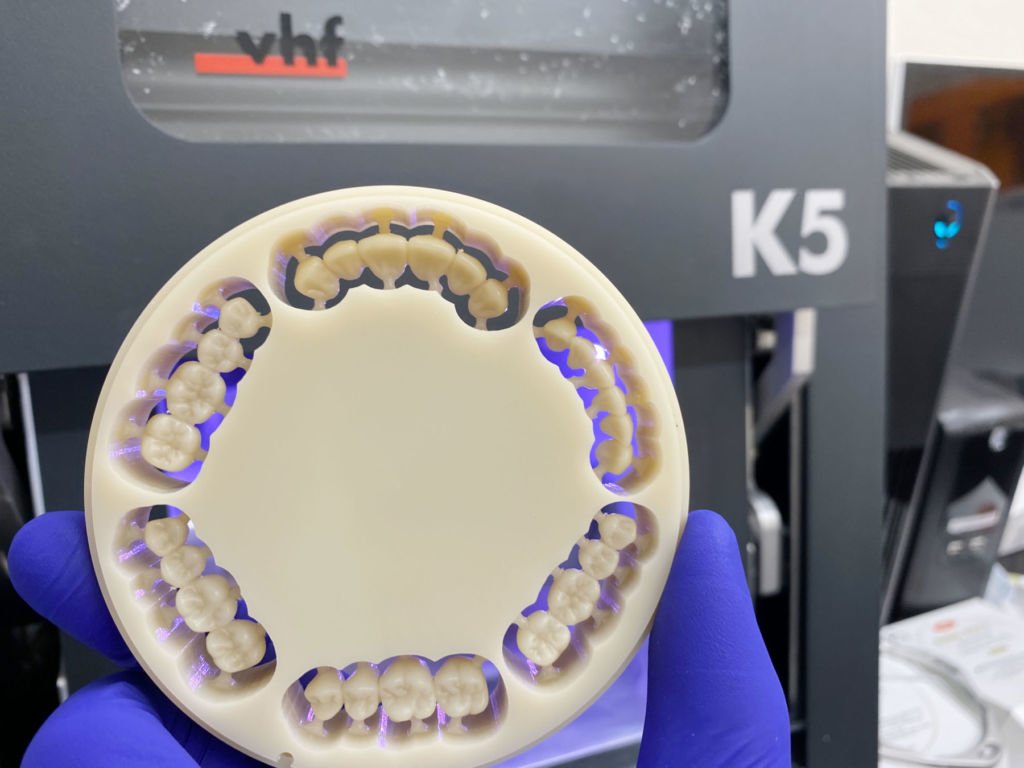

After extracting the teeth, we brought in scans of a wax-up denture tried in the mouth to help establish his incisal edge position and smile arc. At this point, we could go through the step-by-step functions in exocad software to help design maxillary and mandibular prostheses, which at this point, are essentially dentures! After designing the dentures, exocad Plovdiv automatically creates pockets for teeth arches that when milled or 3D printed, teeth segments can fit into a prepared base! So exocad prepared 3 segments of teeth “bridges” for each arch, teeth #2-5, #6-11, #12-15; #18-21, #22-27, #28-31. This is a new feature as previously this wasn’t possible with exocad software!

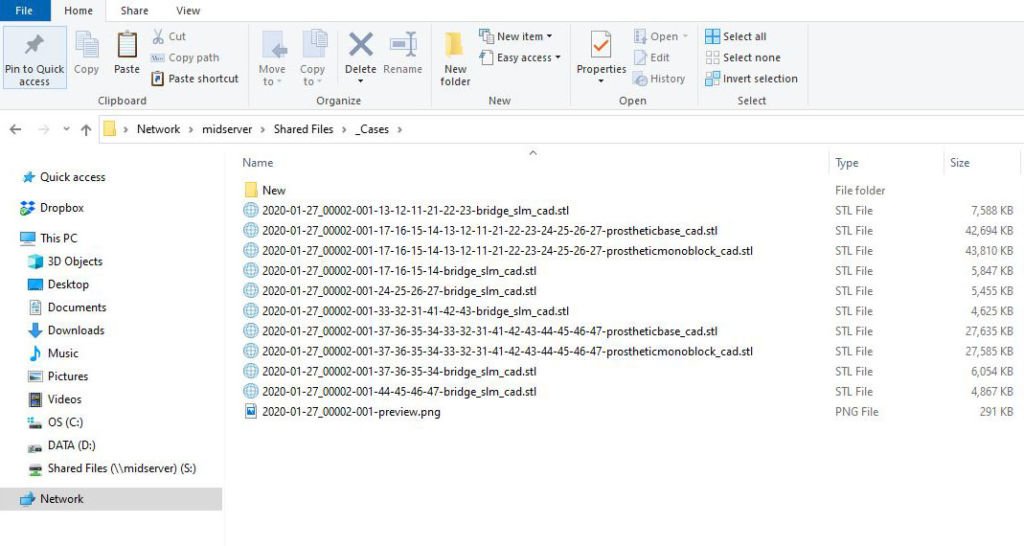

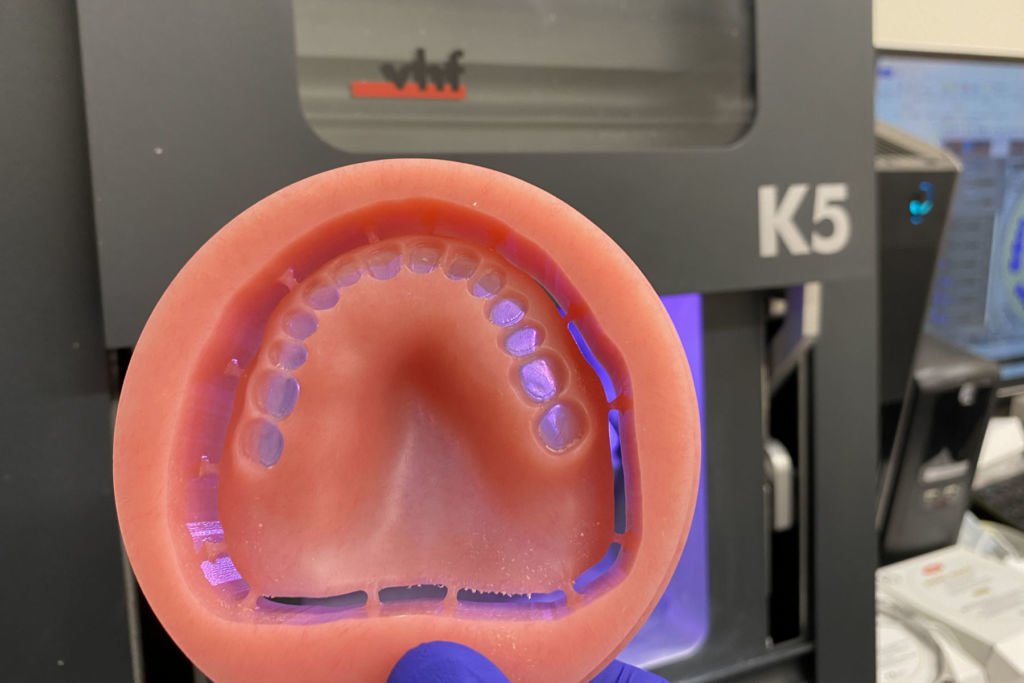

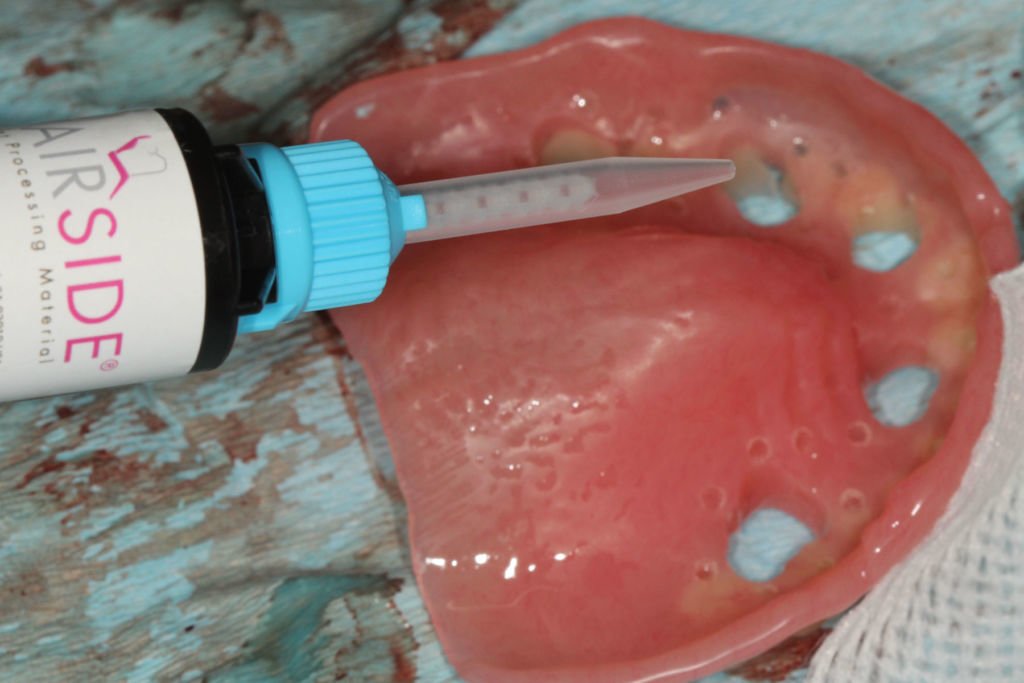

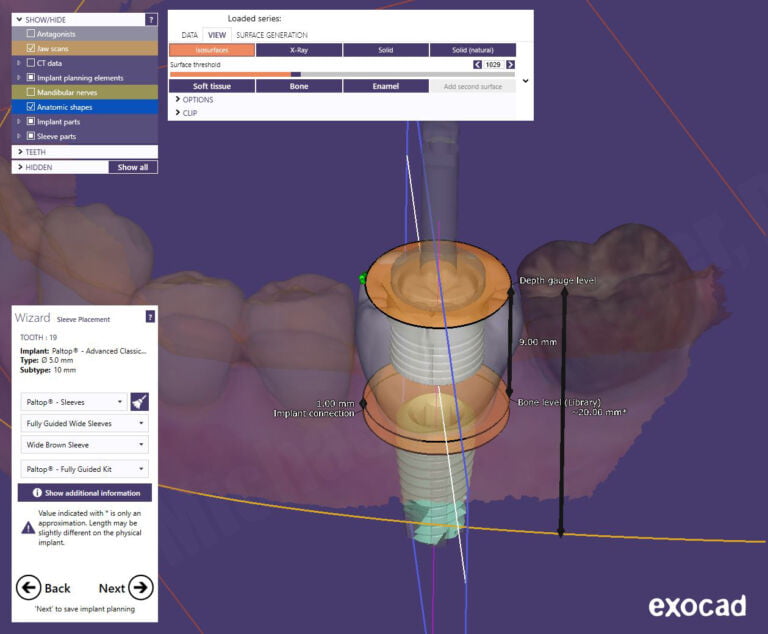

Once the design has been totally created, we now have a folder full of STL files including a file for each segment of teeth “bridge”, a denture base for each arch, and also the software pops out a monolithic denture too! This was helpful for me for being able to prepare a surgical guide for the AllonX case! We milled the teeth arch using Pearson Dental Supply Vivid A2 and milled the base using Dentsply Lucitone 199 base resin. We printed the monolithic dentures with a few holes cut out on a Form2 using Dental SG resin. The teeth were polished and luted to the milled base using Ivoclar’s digital denture bonding system.

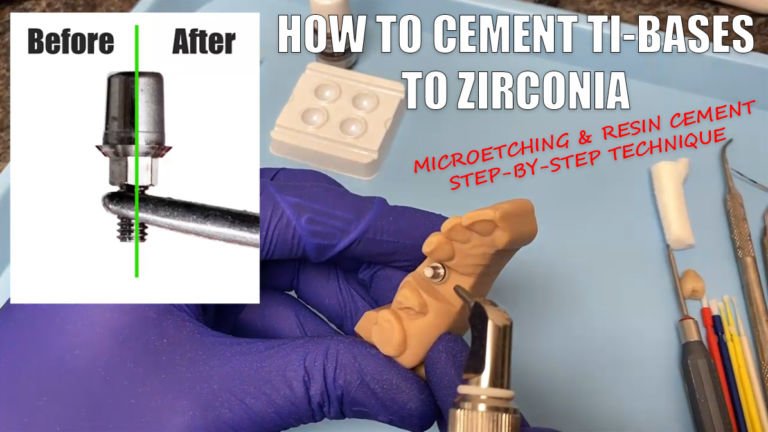

So now that we have a milled digital denture, converting it into an AllonX prosthesis using very standard and traditional methods, no fancy stuff here! Why? Just because it works and sometimes you just gotta do analog to get the job done too 🙂 The key here is that we have an extremely strong milled interim prosthesis, fully produced via digital workflows with 3Shape Trios, exocad Plovdiv, and a VHF mill.

Interested in learning more about CBCT, implant planning, 3D printing, and some amazing step-by-step guided surgery protocols in your office and/or laboratory? Check out our innovative step-by-step online digital dentistry course at www.LearnDental3D.com

Dr. Michael Scherer, DMD, MS

Dr. Michael Scherer is an Assistant Clinical Professor at Loma Linda University, a Clinical Instructor at University of Nevada – Las Vegas. He is a fellow of the American College of Prosthodontists, has published articles, books, and in-person and online courses related to implant dentistry, clinical prosthodontics, and digital technology with a special emphasis on full-arch reconstruction.