“Nobody Could Exactly Copy My 52-Year Old Denture… Until Now!”

If you treat enough denture patients you’ve likely got those patients – you know, the ones that come in seemingly griping, “I need a new denture, but I’ve had my denture for years and I just want a new one similar to my current one, I like how it fits!” Maybe you even have those same folks who come in saying, “those other dentists couldn’t make me a denture that’s right… but I KNOW you can do better.” Patients like this can be a big reason why some dentists don’t like treating denture patients… but it could also be the biggest reason why some do!! The removable challenge is set!

Recently, one of those “tricky” patients presented to my office for a new patient evaluation with the notes attached to her chart – “NP drives from 5 hours away – has had multiple other dentists around the country try to make her a new denture no luck, patient wants new denture and says you can do it.” Oh man… talk about setting me up for a challenging day!

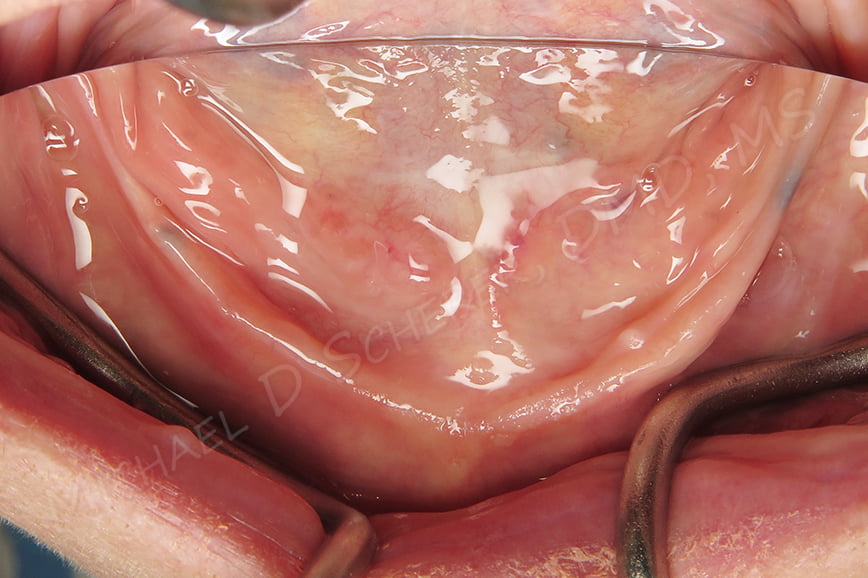

I met the patient and she’s extremely kind and friendly, started off very personable and excited about coming to the office. I began speaking with her and she’s extremely educated, a professional, and just frustrated. She tells me her story – she’s been to several other dentists to try to make her a new mandibular denture including several whom are denture experts or focus solely on dentures. She’s even traveled around the country to find those dentists, I didn’t ask how many but it was many. She tells me why – she’s worried. I ask her “Why are you worried?” She’s happy with the maxillary, it’s big, tough, and stable. She’s worried about her mandibular denture. It’s worn down, small, and one drop away from disaster. She shows me her denture, it’s a 52 year old denture. She’s 70.She’s had the same mandibular denture her entire life.

After going through our examination, I know why other dentists have had such trouble making her happy. According to dental school academic goals, her existing mandibular denture falls quite short of the established standards. The occlusion is worn, stability is poor, esthetics are questionable, and vertical dimension, which is often the most important, is clearly not even in the ballpark. I show her all of these things and she says, “Doctor, I’m so used to it the way it is, it just works. It’s a part of me for the past 52 years!”

I’ve had many patients over the years who came in with old beat up dentures asking for new dentures only to find out brand new dentures will feel and fit quite a bit different from their existing set. Thankfully, most get used to them and understand the “new shoe break in experience.” Our patient today does not want to go through that experience. She knows what she wants – “Doctor please make me a new denture that’s the same as my trusty old denture…. just with a bit of a refresh on the biting surface.”

All of this build up sets the stage, but she came to me for a reason. I have spread the word over the years about how digital technology can be leveraged to do incredible things. Our patient sought me out because she has read up on me. Lol, that may be a kind of scary thing for sure! She had to drive past countless numbers of other Dentists/Prosthodontists to get to my office. I have found pushing digital innovation help drive patients to the dental office and bringing in the latest in technology helps grow a dental practice!

How can we go about addressing her needs? Is our technology up to the task? We had a thorough discussion, I explained the process to her about duplicating the denture using special technology. The denture wouldn’t be exactly the same, but it would be as close as humanly possible and based upon what we could accomplish with manufacturing technology. She said “yes” and was on board. Let’s get started!

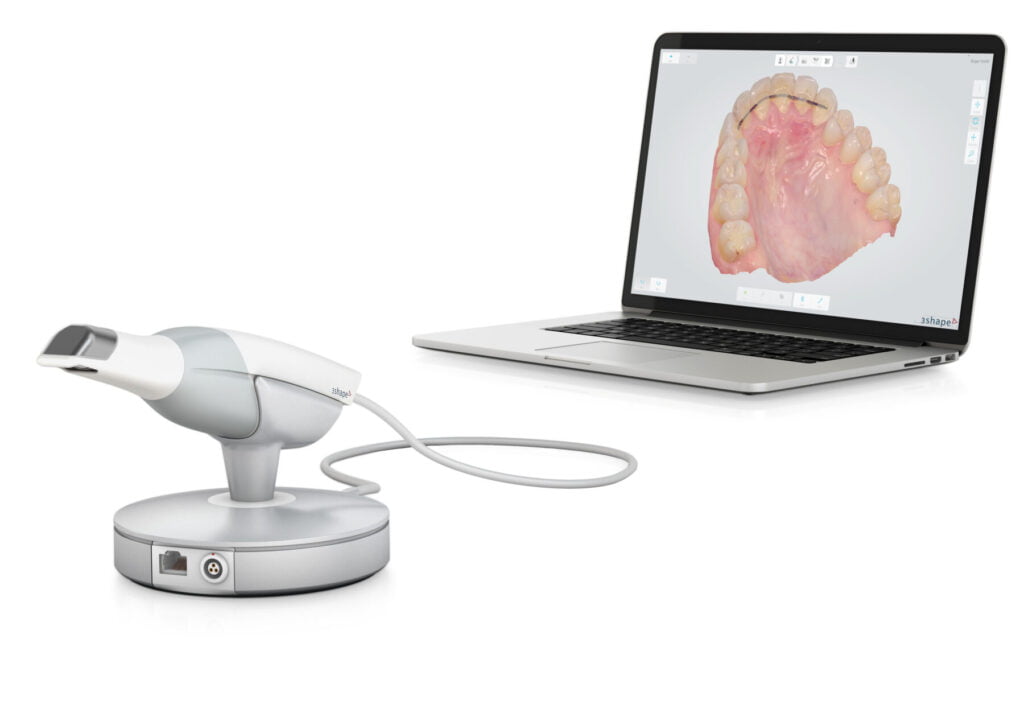

Enter 3Shape and the combination of their TRIOS intraoral scanner and the recent software update of allowing scanning of dentures. On top of it, exact denture duplication using the latest version of the Dental System software. Going from clinical to laboratory-based software can be intimidating for some clinicians but fear not, it’s actually quite simple once you get a few cases down!!

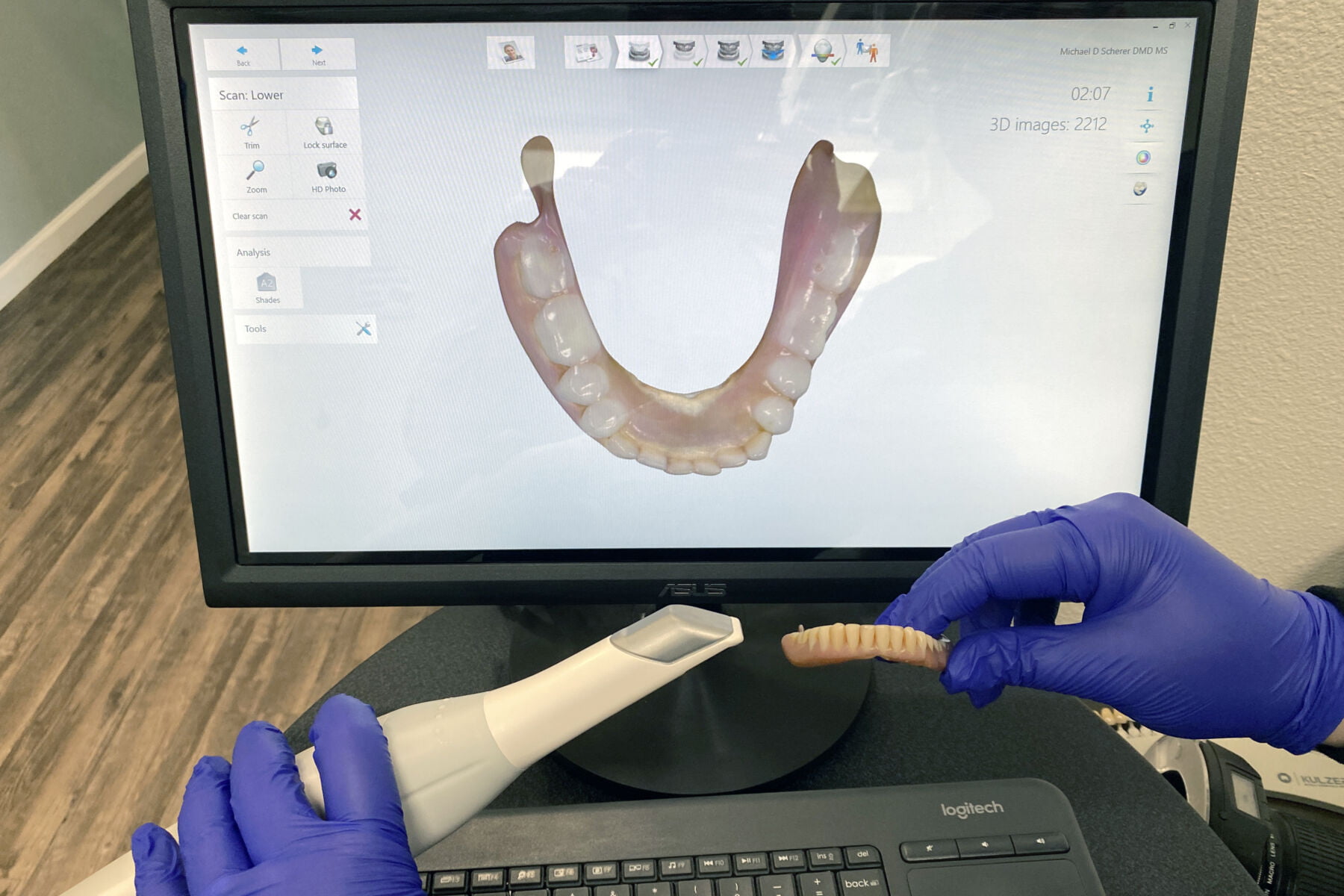

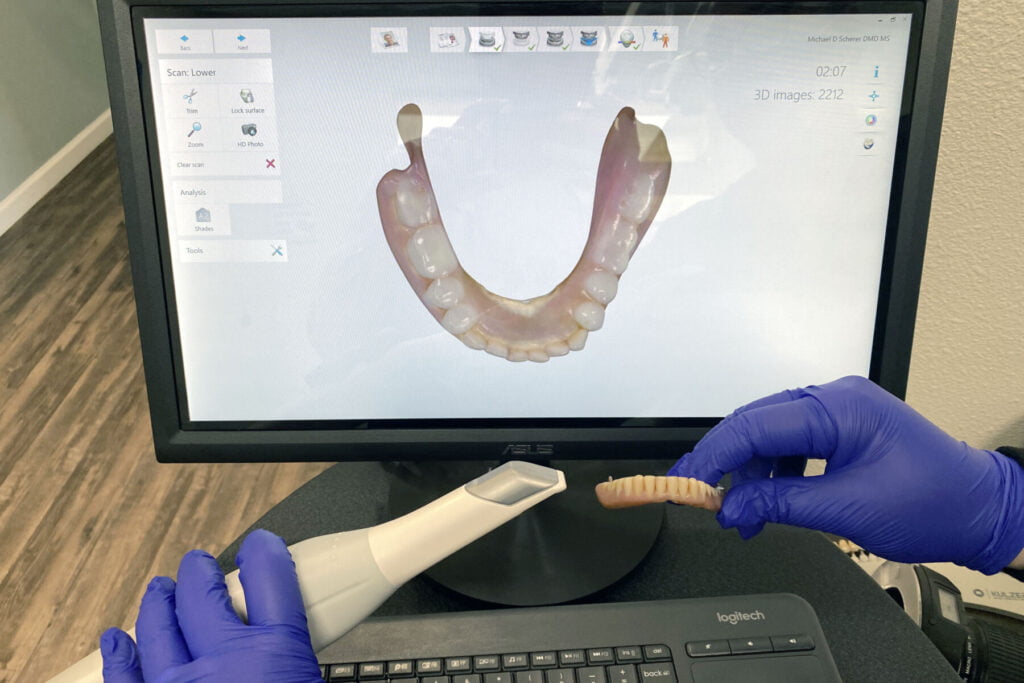

I scanned her mandibular denture using my 3Shape TRIOS scanner using the special new update allowing for very simple scanning methods of impressions and dentures. I have covered this scanning technique before but the approach is very similar to the “reference denture technique” scanning protocols. Two minutes and seven seconds later, I had her denture fully scanned, 360 degrees. While I could have scanned her maxillary denture as a reference, I didn’t need to scan anything in her mouth, nor did I need to scan her maxillary denture. I’m going to make as close to an exact copy of her denture as possible. Who needs an opposing? So I handed her back her denture and said we can make her denture overnight and it will be ready tomorrow if she wanted to stick around town instead of having to drive back 5 hours only to return again.

“What!!” she said. She was blown away. I told her we could actually do it faster with 3D printing but to get the color of the denture base and considering the thinness of the denture itself, I was worried a printed denture wouldn’t be strong enough so I wanted to mill it. Her appointment was scheduled the following day and she left very happy.

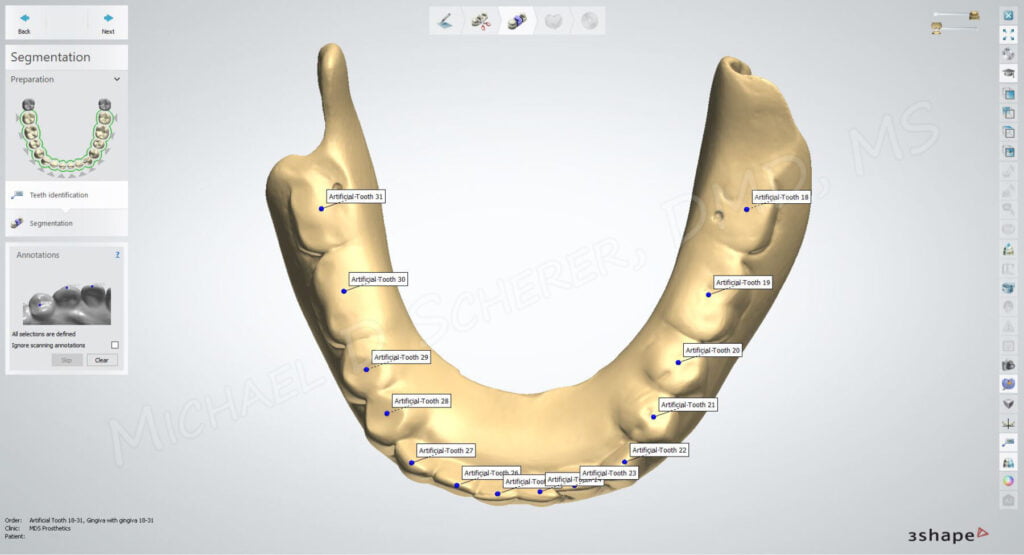

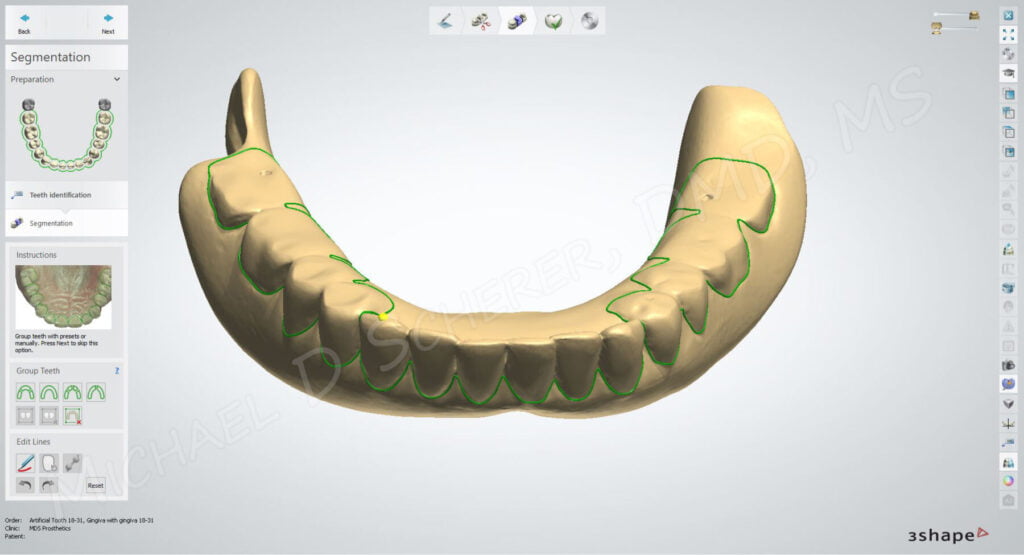

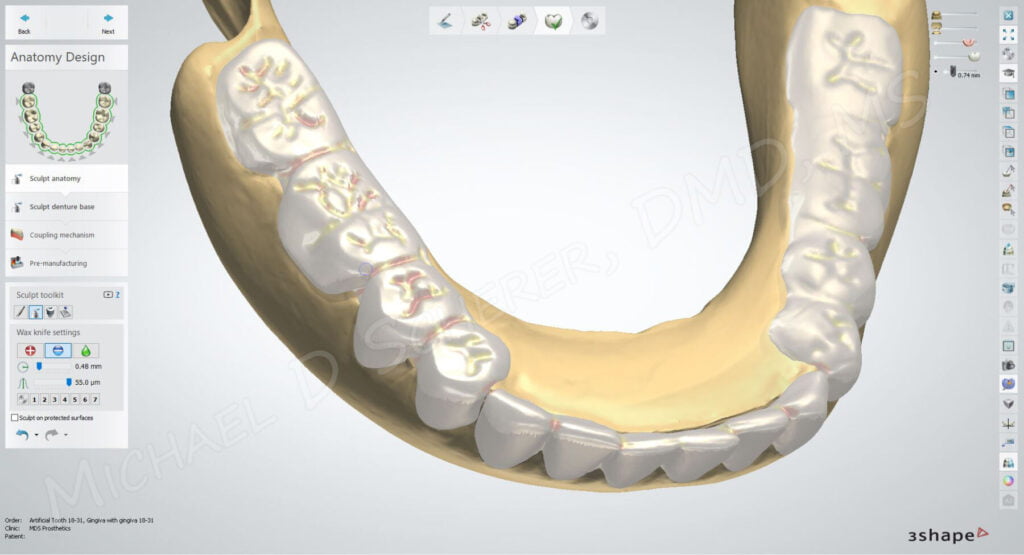

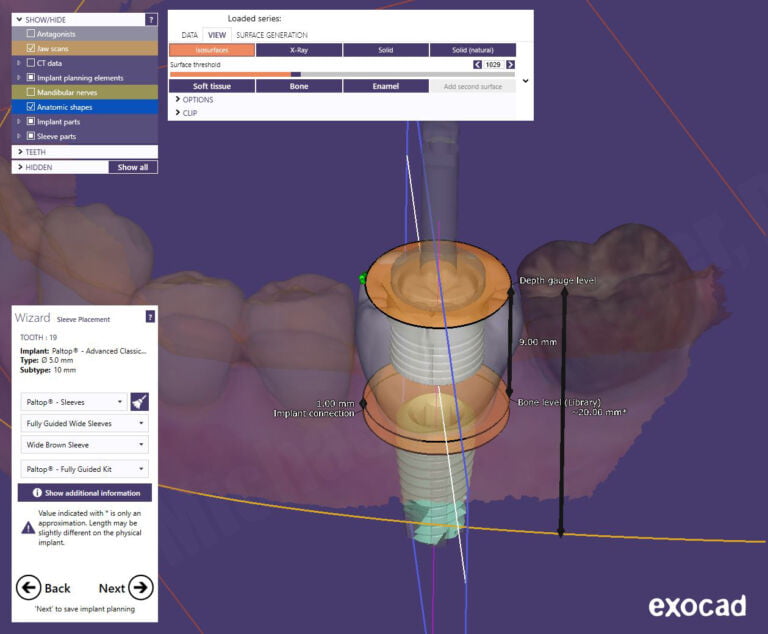

I imported her scans into my 3Shape Dental System software and began the digital denture production using the copy denture function. This innovative new concept is fully built into the software, no special “hacking” needed!!

The software takes you through the wizard step-by-step process to make a copy denture. First you mark where each tooth is followed by the software segmenting out the gingival necks of each of the teeth. Some minor modifications are often necessary but the software is intelligent enough to know where the denture tooth begins and ends.

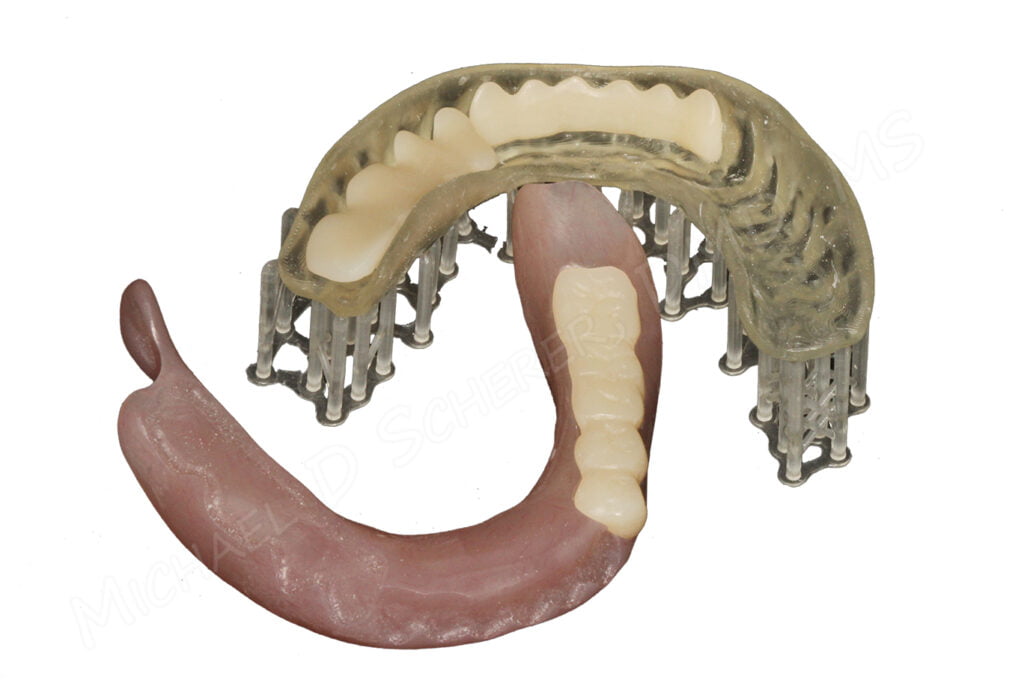

I wanted the software to build 3 segments of teeth, one for each posterior segment and one for the mandibular anterior teeth. This 3-piece section design greatly simplifies manufacturing and saves on material costs, enabling us to keep our costs down for this procedure (which we charge a fraction of our normal denture fee to copy a denture). Knowing the patient requests a bit more occlusion and anatomy, I carved in some anatomical features into the posterior teeth. There’s not much to work with, but I can give her a bit more “grip”!!

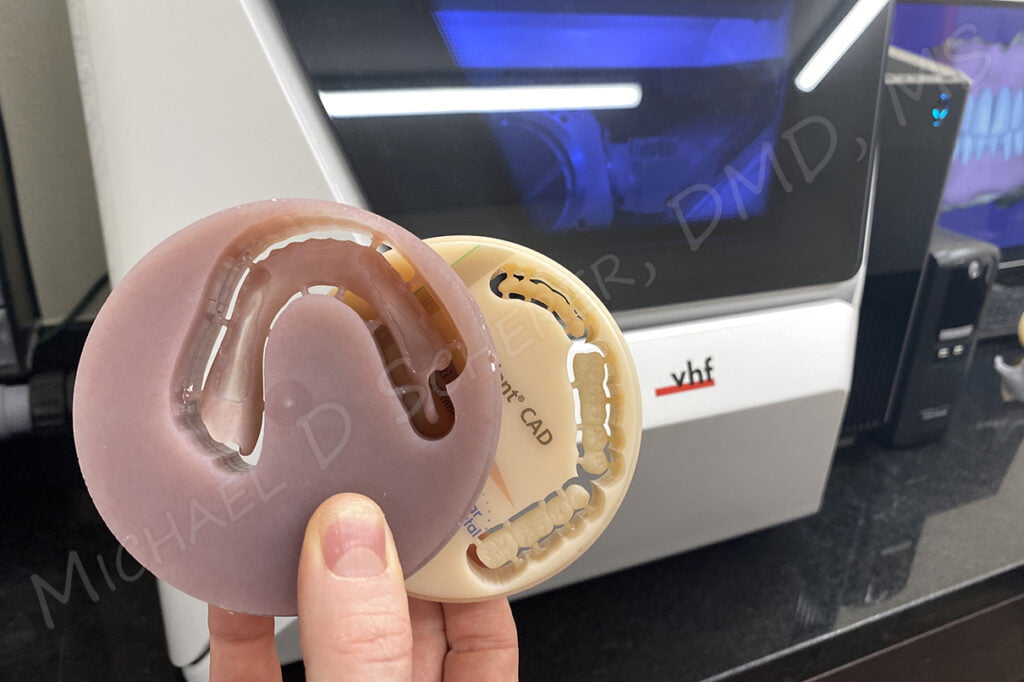

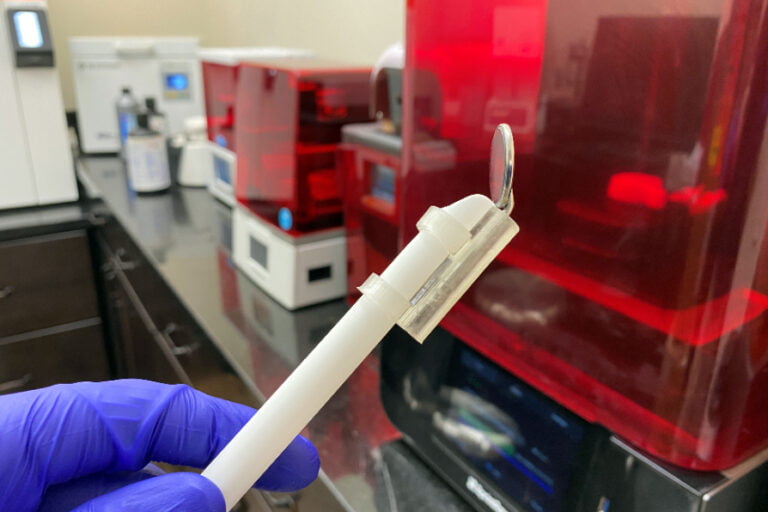

3Shape Dental System outputs the STL files automatically and makes it easy for them to go into the milling machine or 3D printer. I decided to really put my new VHF R5 milling machine to the test! It was late and milling dentures can often take a few hours per denture but the R5 allows me to program up to 10-discs in the changer. I put in the Ivoclar Ivotion dark pink denture base and the multi-layered tooth segment and I just went home. I came back in the next morning and denture base and teeth are milled perfectly!!

I handed the teeth off to my in-house technician to do his magic. He prefers to use a special 3D printing occlusal position jig/device that the software outputs the design and I just click print. It helps stabilize the teeth in the right position before bonding together. Each segment pops right into the 3D printed template and special bonding material is used to bond the teeth to the base, using the template to help ensure the teeth don’t move or get displaced during the process. After bonding and a quick polish, the denture is done and the patient is on her way back to the office!

With the patient back int he chair, I had a chance to evaluate the newer versus the older denture side by side. You can really see how the scan – design – mill functions can really make for pretty incredible results even in challenging cases. The general shape and contours are spot on! So far so good!

I gave the new denture and had our patient put the teeth in her mouth. Her first words are, “Wow… I don’t know what to say…” I hold my breath for what feels like eternity butwas really only a few seconds. She then remarks, “…. it feels exactly the same!!” Phew, I’m relieved. I gave her approximately 10 minutes to walk around the office, go outside, check out her teeth in various angles just to make sure.

She returns and remarks indicates that she thinks her new teeth actually feel better than her old teeth. As she tears up a bit saying how far she has traveled and how long she has tried over the course of 52 years she can’t believe how digital techniques can do what they did for her. She can’t wait to tell her friends that she loves her new denture – a true digital denture success story!!!

Interested in learning more about digital dentures including clinical and laboratory techniques and protocols? Check out our innovative step-by-step online digital dentures course at www.LearnDigitalDentures.com

Dr. Michael Scherer, DMD, MS

Dr. Michael Scherer is an Assistant Clinical Professor at Loma Linda University, a Clinical Instructor at University of Nevada – Las Vegas. He is a fellow of the American College of Prosthodontists, has published articles, books, and in-person and online courses related to implant dentistry, clinical prosthodontics, and digital technology with a special emphasis on full-arch reconstruction.