Isopropyl vs Ethyl Alcohol – Which Should I Use For 3D Printing?

For many of us who have been involved with 3D printing for sometime, we’ve got the methods down. – design, export, import into printer software, mix resins, fill tank, click print, come back later, remove build-platform, remove resin from build-platform, clean platform, wash prints in alcohol, dry, UV cure.

Post-processing is the biggest secret of 3D printing – it just sucks…”

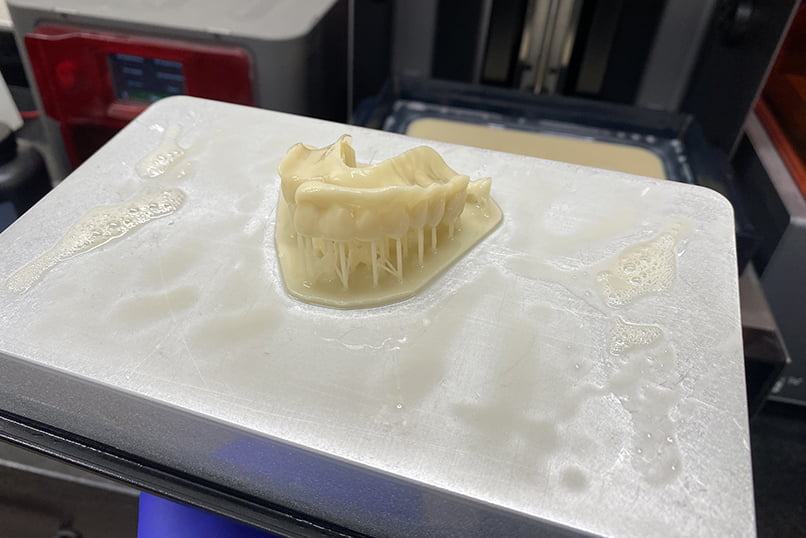

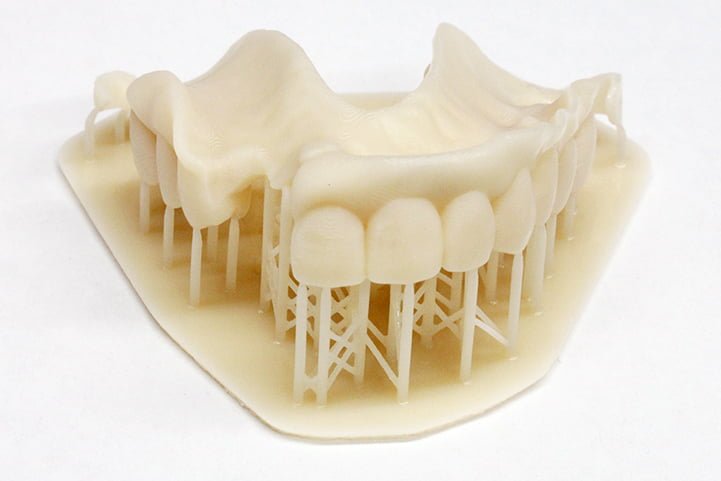

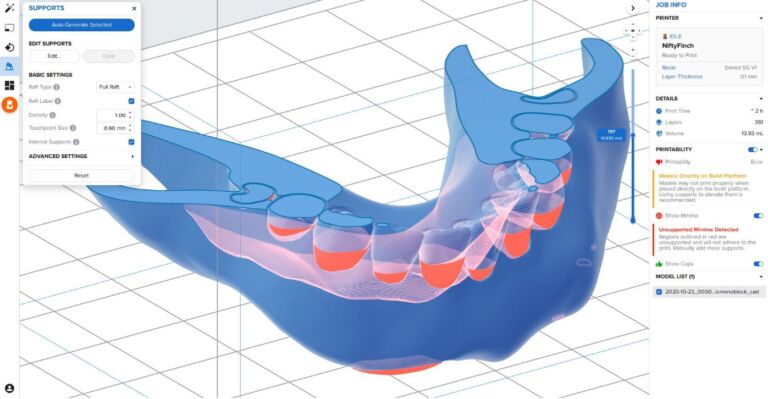

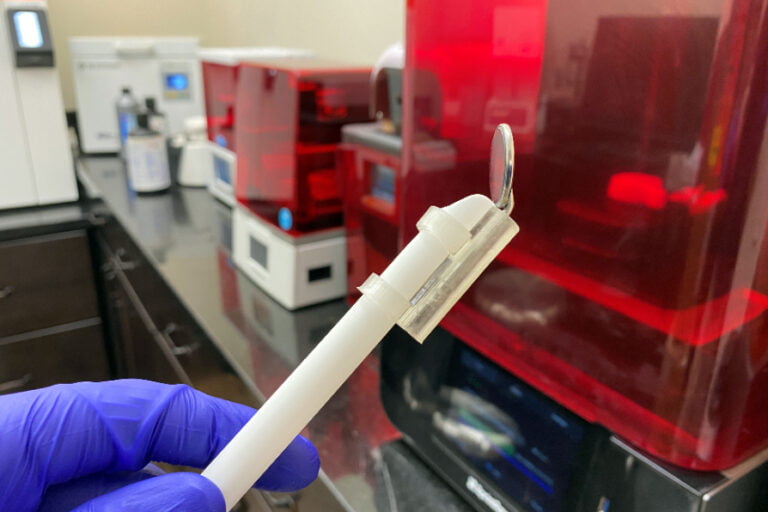

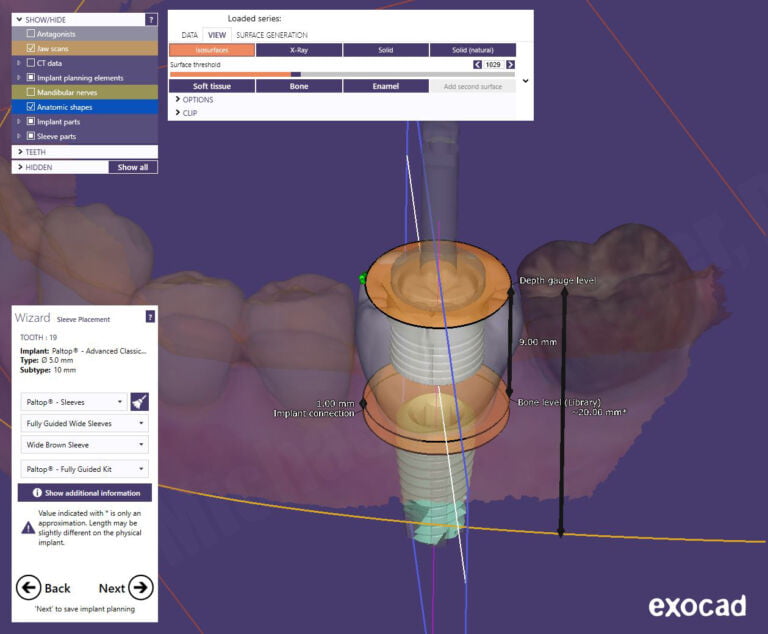

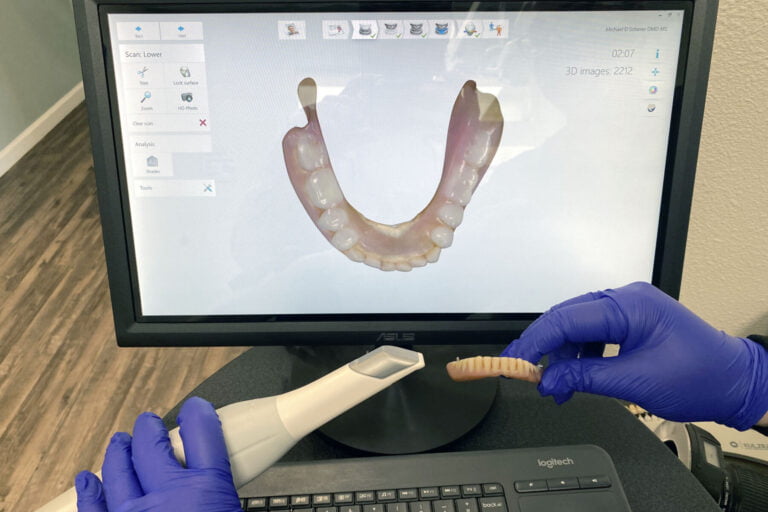

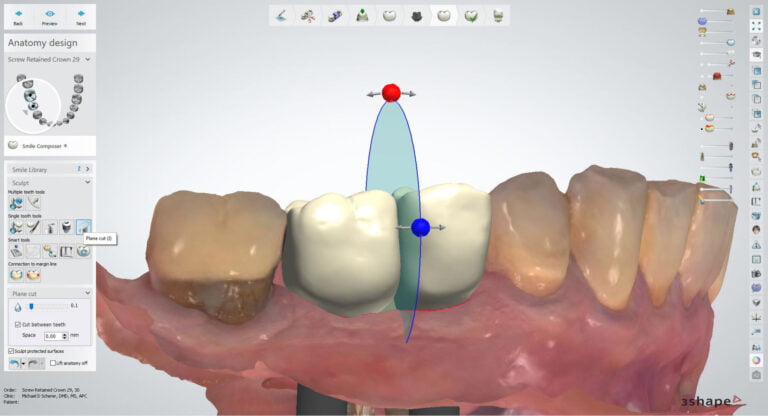

For those who do this on a day to day basis, it represents a seemingly whimsical like procedure analogous to an orchestral conductor timing a great concerto. Well… we kind of wish that it was something as cool as that, but in reality, it’s simply a necessary drudgery until systems that can automate print-wash-cure cycles, like the Structo Velox, are more common. For now? We go through the routine of taking a stereolithography resin print, like that from a Formlabs Form3, SprintRay Pro, or 3D Systems Nextdent 5100 3D printer and wash away the liquid layer of resin that remains on the surface of the 3D printed object. Additionally, after the object has washed and dried, we finalize it with a UV curing cycle. This cumulative wash-dry-cure cycle is termed “post-processing.” Frankly, post-processing is the biggest secret of 3D printing- it just sucks… but it works.

For this article, let’s focus on one key part of that post-processing cycle: the wash solution. Since most stereolithography 3D printers use a liquid resin to print, when an object comes out of the printer, it has a sheen on it of uncured resin, just like washing a bowl in the sink and soapy water sheen is seen on the bowl. Soap is water-soluable, so all we need to do to wash a bowl is to rinse it under water. Resin, for most stereolithography printers, is not water soluble, since they are based upon a methacrylate or acrylic esters. Resins, however, are soluble in alcohol.

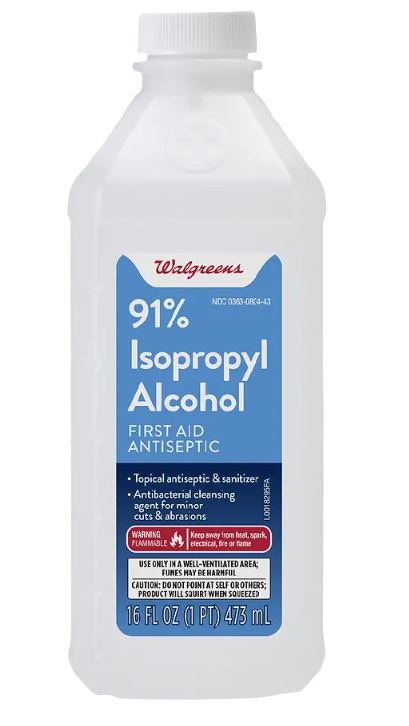

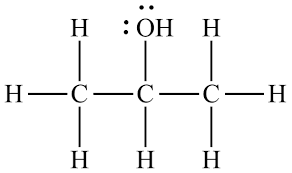

The most common alcohol used for washing resin 3D printed objects is isopropyl alcohol (IPA) and it’s chemical formula is C3H8O. Why? It’s simple to get just about anywhere and it has withstood the test of time. It comes in 3 different commercially available common strengths: 70%, 91%, and 99%. So what makes up the extra 30, 8, and 1% respectively? Water.

Frankly, IPA works fantastic for 3D printing applications. It’s reliable, simple to purchase anywhere, and has a tremendous amount of flexibility. The biggest drawbacks of using IPA is that it is one of the more flammable alcohols used in a laboratory, it’s a bit more expensive compared to ethyl alcohol, and it has a strong smell.

IPA has three concentations. Many of us are used to using 70% IPA around the house. It’s excellent as a cleaner for sticky tape and also serves as a great way of disinfecting cuts or scrapes. The benefit of using 70:30 alcohol to water ratio is that it’s gentle on skin and floors around the house. The negative of using that ratio for 3D printing is that it doesn’t clean the resin well enough. I do not recommend using 70% IPA in 3D printing.

So that leaves 91% and 99% IPA. For around 3 years or so I kept this dance going between the two strengths. I said to myself, “Wow I can get 91% IPA at the local store” versus “Wow wouldn’t it be awesome to use something that’s 99% awesomeness versus 91% awesomeness?” Yeah, I have no life, I get it. So for years I preferred 99% IPA for my early 3D printing projects and would routinely use the stronger 99:1 ratio for models. As surgical guides and, more importantly, occlusal guards and temporary resins became available, I learned through Edisonian approach that the stronger ratio was giving me strange results and weird finishes on the prints. I reverted back to the 91% IPA as the 91:9 ratio of alcohol to water was a bit gentler on my 3D printed parts. I typically advocate for using either alcohols and I go into detail and clinical recommendations in our online 3D printing course about how to use one or the other.

For those who are worried about the flammability of IPA, make sure you check out this amazing video of isopropyl burning compared to ethyl alcohol and methyl alcohol. Some caution dental offices and 3D printing laboratories that objects should be washed under a fume hood. Wow, that would be tough to get installed in a dental office. What other options does the dental office have for washing their prints?

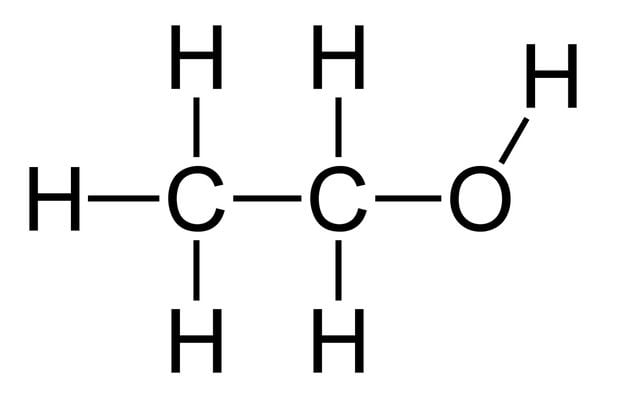

Ethyl alcohol (Ethanol) is very similar in chemical formula C2H6O compared to IPA (C3H8O). Additionally, it functions very similarly but with a few amazing benefits to the 3D printing laboratory. Typically, commercially available ethanol is produced 95% ethanol and 5% water. Used commonly in automobile fuel in E85 gasoline blends, ethanol is very popular throughout the country as a fuel. Additionally, it’s cited as a renewable form of energy that’s produced typically from corn, so it kind of makes us feel a little less worse about using so much of it to clean our 3D prints! While negative impacts upon ethanol are apparent and it’s “clean-energy rating” is subject to debate, the bottom line is that it’s commonly available, easy to get, has a wide supply – thus means that we can also get it a bit cheaper compared to other alcohols.

I got introduced to the use of bio-ethanol when I was teaching in Belgium at a course hosted by Stijn Hanssen with DigiFlow3D. He said to me, “Here in Europe, IPA is much harder to get, so we tend to use a lot of bio-ethanol.” Hmm… interesting? We had quite a long chat about it’s benefits compared to that of IPA. A little bit easier to get, check. A little less expensive, interesting. A little less volatile chemical smell, awesome sauce! Finally, it’s flammability is lower than that of isopropyl alcohol, superb!! Check, check, check, check. Seemed like a winner and it’s amazing what we learn when we collaborate. The big question is why they just didn’t use IPA in Europe much? Turns out it’s much harder to get because of it’s perceived higher flammability risk compared to suitable alternatives. Interesting! So when I returned home, I immediately put it to the test.

I discovered that many of the benefits were true, I really started to enjoy working with bio-ethanol products to clean my 3D printed models, dentures, surgical guides and many others. I did find, however, that I felt like it wouldn’t be able to fully replace the use of IPA in my laboratory. I liked that it had less of a volatile chemical smell, that ultimately made myself and my technician very happy. Also, I liked how I could buy it affordably compared to IPAs. What I didn’t like is that I couldn’t just run down to my local dollar store and buy it. Yeah, I know we can just purchase things on the internet these days, but I also have a scatter-brain and it’s just really nice to pick up a few bottles on the way to work.

Necessity is the mother of invention/development, so I totally understand why in Europe, where it’s harder to find IPA, the preference is bio-ethanol. Would they use IPA more often if they could buy it down at the local dollar store? Maybe, maybe not. What I do know is that in this world of COVID-19 where people are buying out IPA out of the stores, thankfully, we still can easily find and purchase bio-ethanol (for now… sssh).

Interested in learning more about 3D printing and some amazing step-by-step protocols on how to get on the fast track in your offices and laboratories? Check out our amazing step-by-step online course at www.LearnDental3D.com

Dr. Michael Scherer, DMD, MS

Dr. Michael Scherer is an Assistant Clinical Professor at Loma Linda University, a Clinical Instructor at University of Nevada – Las Vegas. He is a fellow of the American College of Prosthodontists, has published articles, books, and in-person and online courses related to implant dentistry, clinical prosthodontics, and digital technology with a special emphasis on full-arch reconstruction.